Introduction:

In today’s world, where technological advancements are reshaping various industries, materials with exceptional strength and versatility are highly sought after.

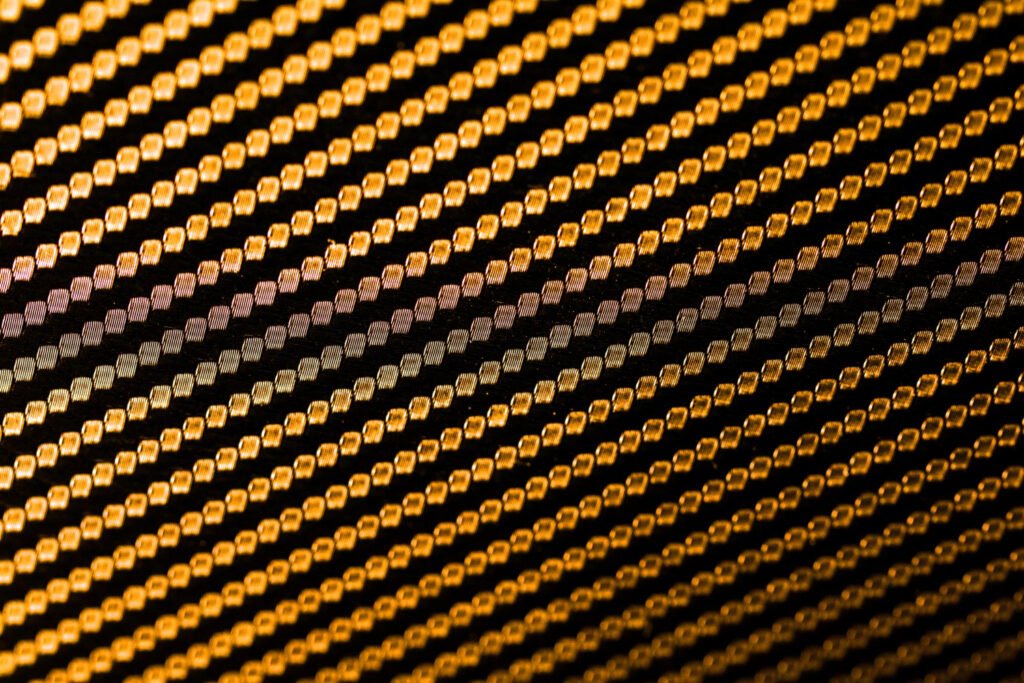

Out of many such materials, Aramid Fiber stands out as a true engineering marvel. Renowned for its exceptional strength, heat resistance and lightweight nature, aramid fiber has become an indispensable component in a wide range of applications, from aerospace and defense to sporting goods and automotive industries.

In this blog post, we will delve into the world of aramid fiber, exploring its unique properties, manufacturing process and the diverse applications that benefit from its remarkable characteristics.

Understanding Aramid Fiber:

Aramid fibers are a class of synthetic fibers with high-performance characteristics derived from their unique molecular structure. The term “aramid” is derived from “aromatic polyamide,” referring to the aromatic rings that form the backbone of the polymer chains in these fibers.

The most common types of aramid fibers are para-aramid and meta-aramid, with each exhibiting specific properties suitable for different applications.

Properties that Set Aramid Fiber Apart:

- Exceptional Strength:

Aramid fibers possess exceptional tensile strength, making them stronger than most other commercial fibers.

They have a tensile strength ranging from 2 to 5 GPa (gigapascals). Aramid fiber possesses remarkable strength-to-weight ratios, making it stronger than steel on a weight-to-weight basis.

This property is particularly beneficial in applications where high strength is crucial, such as ballistic protection, aerospace components and reinforcements for composite materials.

2. Modulus of Elasticity:

Aramid fibers also have a high modulus of elasticity, which measures their resistance to deformation under stress.

The modulus of aramid fiber typically ranges from 70 to 130 GPa, indicating their ability to maintain their shape and stiffness even under significant loads.

This property is beneficial in applications where rigidity and dimensional stability are critical.

3. Flexibility:

Despite their high strength, aramid fibers exhibit excellent flexibility. They can be bent, folded or woven without losing their strength or structural integrity.

This flexibility enables the production of aramid fiber-based textiles and composite materials, allowing for innovative designs and versatile applications.

4. Heat Resistance:

Aramid fibers exhibit outstanding resistance to heat and flame. They can withstand high temperatures (500 °C) without melting or degrading, making them ideal for applications requiring protection against extreme heat, such as flame-resistant clothing, insulation and thermal shields.

5. Lightweight:

Aramid fiber is significantly lighter than traditional materials with similar strength, making it an excellent choice in weight-sensitive applications. This property enables enhanced performance and fuel efficiency in industries such as automotive, aerospace, and sporting goods.

6. Chemical Resistance:

Aramid fibers possess excellent resistance to many chemicals, including acids, alkalis, and organic solvents. This characteristic makes them suitable for applications involving exposure to harsh chemicals or corrosive environments.

Manufacturing Process:

The manufacturing process of aramid fiber involves several steps. It begins with the synthesis of aromatic monomers, followed by polymerization to form a liquid crystalline solution. The solution is then spun through a spinneret to create individual filaments, which are subsequently stretched to align the molecular chains and enhance their strength. The resulting fibers are then heat-treated and further processed into various forms, such as yarns, fabrics, and tapes, based on the intended application.

Applications of Aramid Fiber:

- Ballistic Protection: Due to their exceptional strength and resistance to penetration, aramid fibers are widely used in the production of bulletproof vests, helmets, and other protective gear for military and law enforcement personnel.

- Aerospace and Defense: Aramid fiber composites are employed in aerospace applications, including aircraft components, rocket motor casings, and radomes. Their high strength and low weight contribute to increased fuel efficiency and improved performance.

- Automotive Industry: Aramid fibers find applications in the automotive sector for reinforcing tires, drive belts, brake pads, and other components. Their lightweight nature helps reduce vehicle weight, leading to enhanced fuel economy and improved overall performance.

- Sporting Goods: Aramid fiber is utilized in various sporting goods, such as bicycle frames, tennis racquets, and protective gear. The fibers’ high strength-to-weight ratio enhances durability and performance without compromising weight.

Industrial and Safety Equipment: Aramid fibers are employed in diverse industrial applications, including conveyor belts, gaskets, seals, and electrical insulation. Their resistance to heat, chemicals, and abrasion ensures reliable performance in demanding.